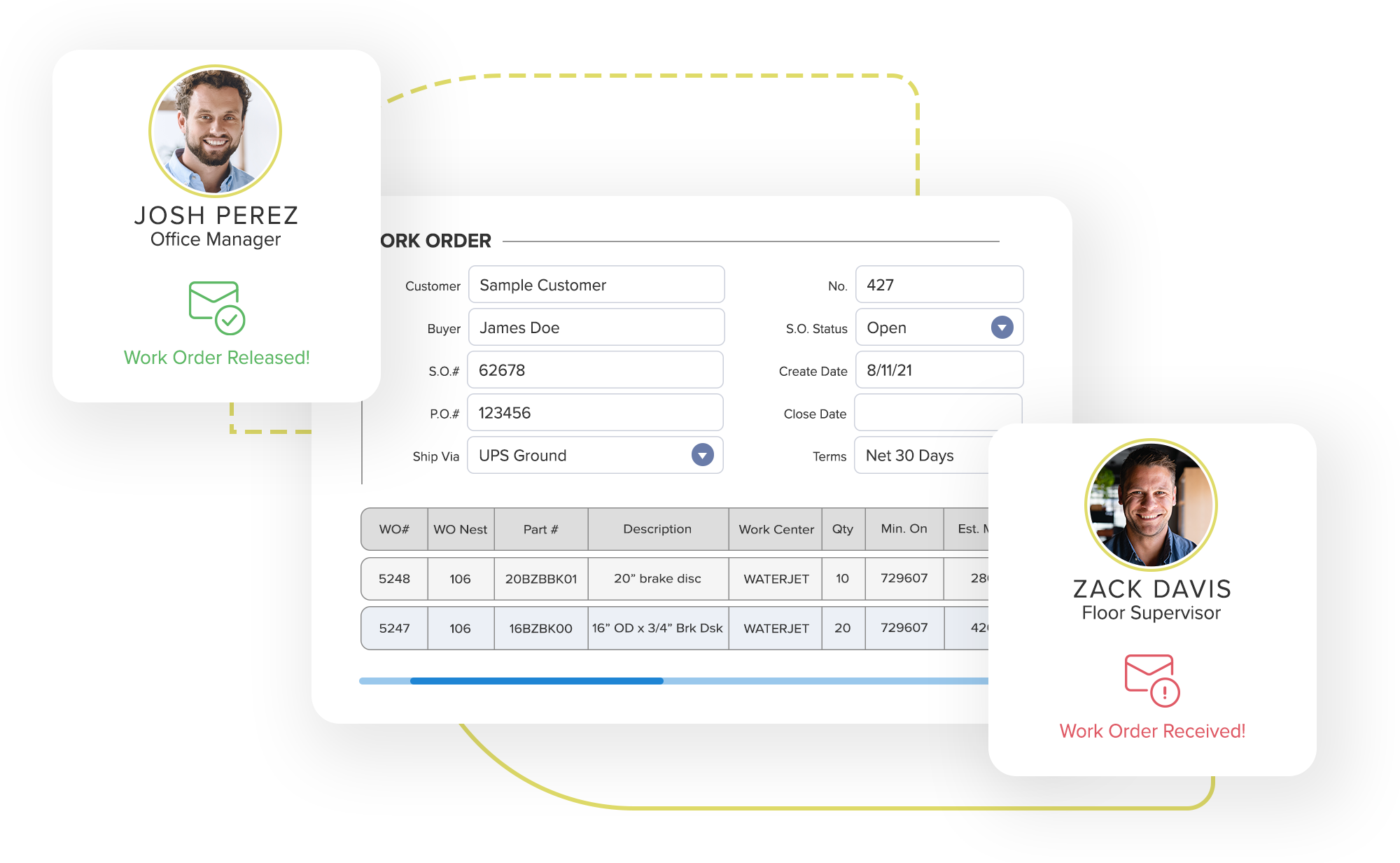

Released by the office. Received by the shop floor. Instantly.

Work orders can be created for made-to-stock, made-to-order, engineer-to-order, Kanban inventory control, and more.

Work orders can be created for made-to-stock, made-to-order, engineer-to-order, Kanban inventory control, and more.

Automate work order creation in several scenarios using MIE Trak Pro. Our system can create work orders based on triggering events including min-max planning, designated reorder points, Kanban replenishment, and sales order demand requirements.

Work order tracking and costing can all be done digitally in MIE Trak Pro. Stop chasing paper around the shop floor and implement a paperless work order tracking system for your business. Track run times, costing, and more as work order processes move forward.

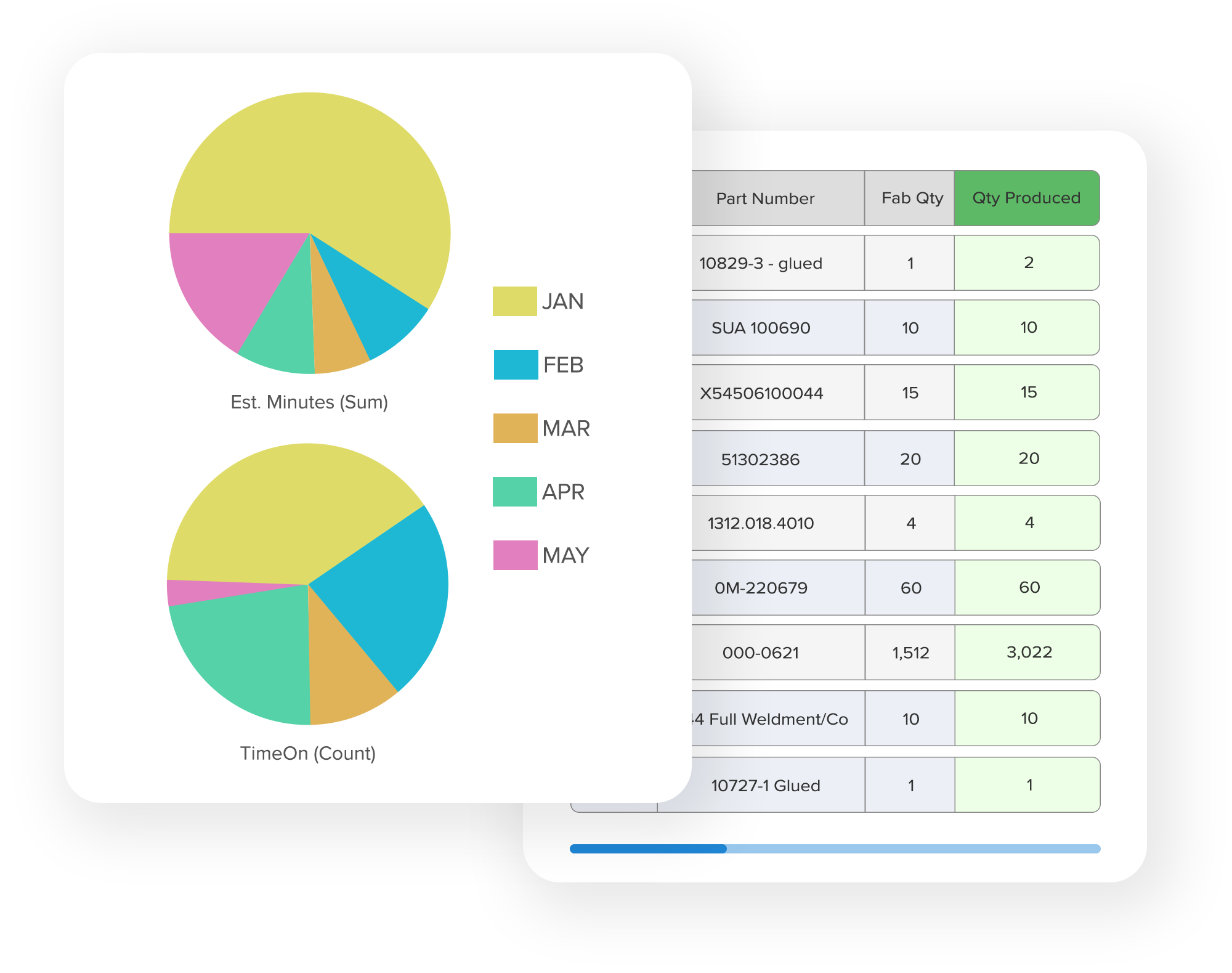

MIE Trak Pro offers a highly efficient tracking system that allows you to see exactly where your product is in the manufacturing process. If it is incomplete at the end of the day, store the product as Work In Progress (WIP) and track the item's storage location.

Here are just a few additional features that you can expect with MIE Trak Pro Work Orders.

Create work orders via multiple routes—including automated triggers, MRP module, reorder points, sales order demand, etc.

Handle single-level or multi-level work orders with as many BOM sub-assemblies as needed

Nest multiple work orders to save time on the shop floor

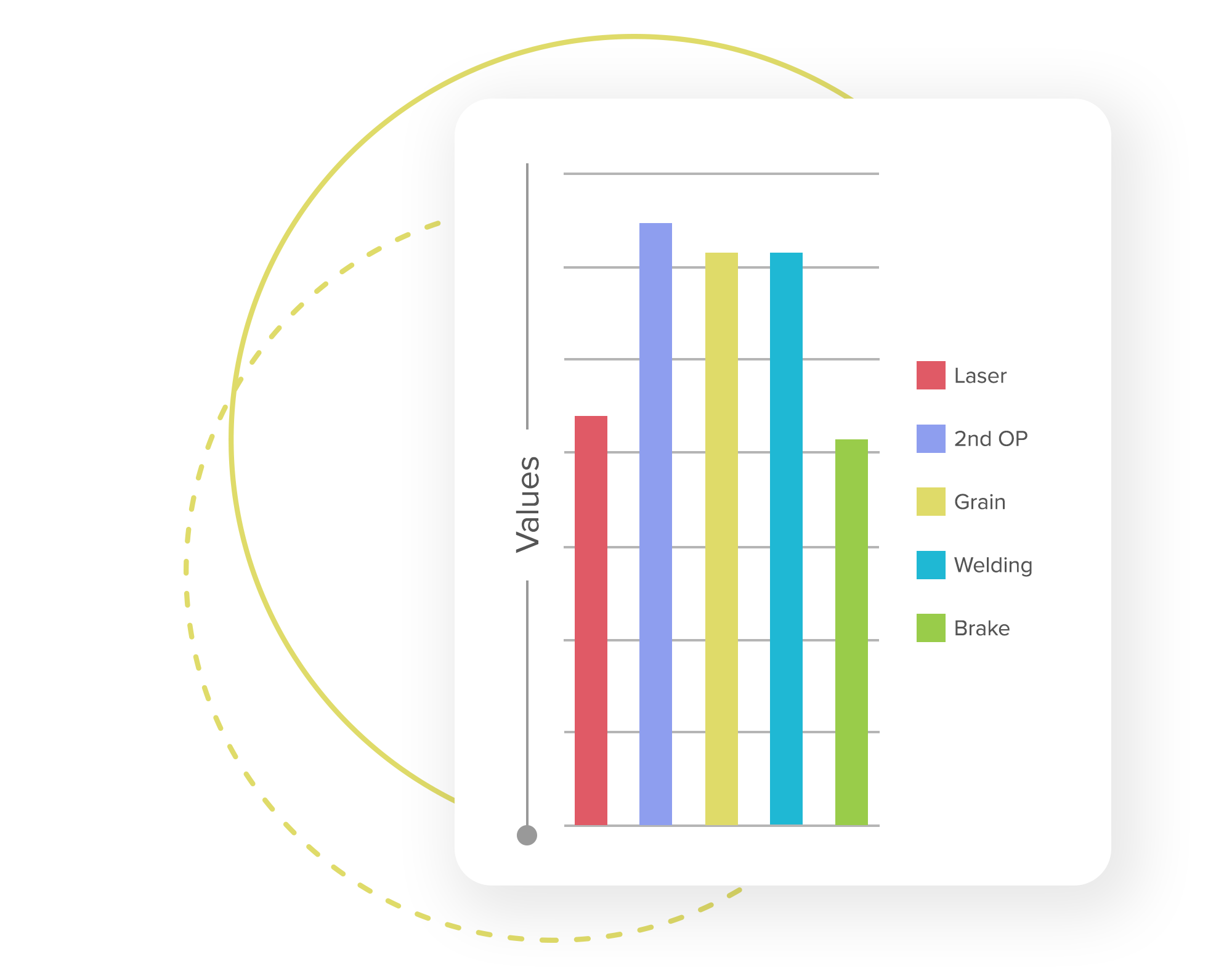

Create efficiency and productivity reports relating to individual (or multiple) work orders

Split work orders if low on supply for separate shipping

Utilize lot traceability for quality assurance

Scroll Through Features

MIE Trak Pro’s quoting functionality allows you to personalize formulas, track win/loss, and create quotes based on true costing data.

Drop a PDF Purchase Order into MIE Trak Pro to automatically create an order or update an existing order based on a change request.

MIE Trak Pro can handle anything from the smallest manufactured part to a 10,000-piece assembly with ease.

MIE Trak Pro schedules accurately using an advanced simulation system so you can stop wondering if the schedule will work.

Create purchase orders directly from a sales order or work order with just a few clicks—no typing required.

Use our warehousing module to simplify material handling—from the issuing, picking, adjusting, moving, and receiving of material.

As scrap quantities are entered, create quality records automatically for up-to-date reporting on the quality of work in progress.

Native reporting features include personalized dashboards for all your business needs, giving you up-to-date information at every stage of production.

A lightweight, tablet-based, data collection system that enables employee efficiency on the shop floor from multiple devices.

See your forecasted cash flow at-a-glance and collect money easier than ever before with a built-in A/R collection system.